SCOTT HARLAN P.E.

Mechanical Engineering

Consultant

Scott Harlan P.E.

California Professional Engineer License M31719

scott@scottharlanpe.com

(831)-210-4645

19518 Creekside Ct.

Salinas, California 93908

ENGINEERING ANALYSIS

- Fatigue Analysis

- Stress Analysis

- Energy Consumption Calculations

Stress analysis is an invaluable engineering tool when applied to mobile equipment design. Weight is an important issue on nearly all pieces of mobile equipment, and stress analysis allows designs to be strong and safe but still lightweight.

When vibration is present, fatigue failures can become an issue. At times fatigue failures occur on components that would seem nearly impossible to break. My experience performing fatigue analysis on motorcycle components can be applied to solve problems on all types of machinery.

When fatigue problems arise, it is not enough to know how to detect them or predict them. You also need to know how to solve them. Often times a change of materials is the least disruptive solution. I have an excellent working knowledge of the different materials available and practical to address these sometimes challenging design problems.

If you have a problem with chronic component failures or just want to optimize a design for weight, I can help.

Both cost constraints and environmental concerns are causing energy consumption to be an increasingly important part of machine design. It is even practical to power some harvesting machinery with solar panels due to the very slow harvesting speeds. I have experience calculating hydraulic power requirements and solar photovoltaic potential for mobile equipment applications. Call me if you would like to investigate the practicality of implementing solar power on your slow moving piece of mobile equipment.

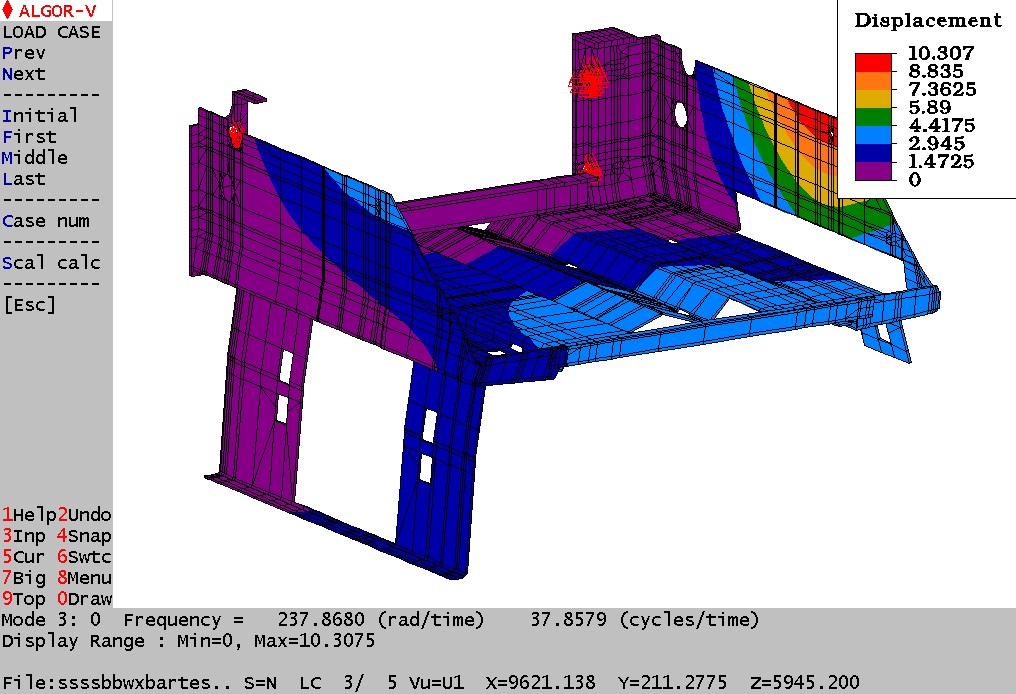

Both vertical and horizontal accelerations were critical design consideration for this wrecker battery support.

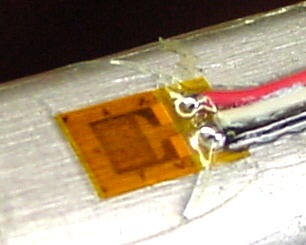

When performing fatigue analysis empirical data to find the magnitude of dynamic loads is sometimes obtained using strain gages. Without these gages it can be difficult or impossible to know the magnitude of vibration induced loads.

Not only was this cruiser motorcycle an exercise in fine automotive finishes, it also required extensive fatigue analysis due to the engine induced loads.